Category

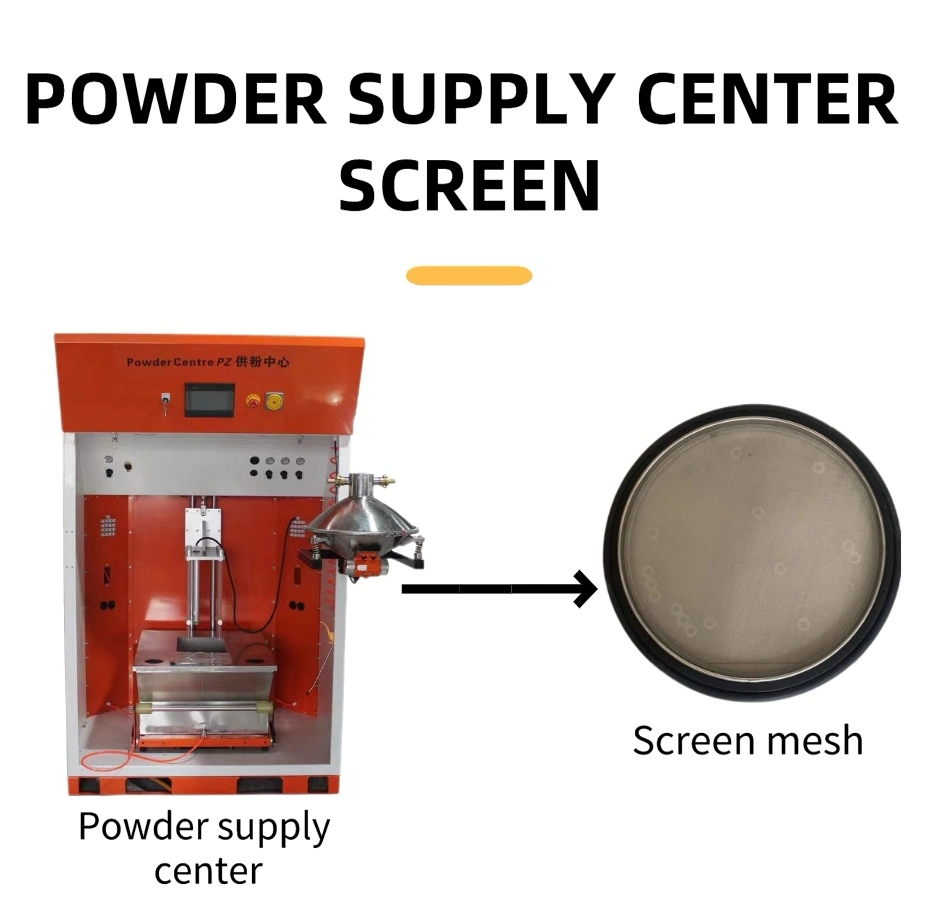

Powder Supply Center Sieving Machine

Product DescriptionPowder supply center introductionAn overviewThe structure of the powder supply center includes: powde

Basic Info.

| Model NO. | ZM-V3 |

| Method Type | Automatic |

| Condition | New |

| Use | The Powder Is Recovered by Filtration and Re-Thinn |

| Transport Package | The Wooden Case |

| Specification | 1300*950*2100mm(Length*width*height |

| Origin | Deqing, Zhejiang Province, China |

| Production Capacity | 3000 |

Product Description

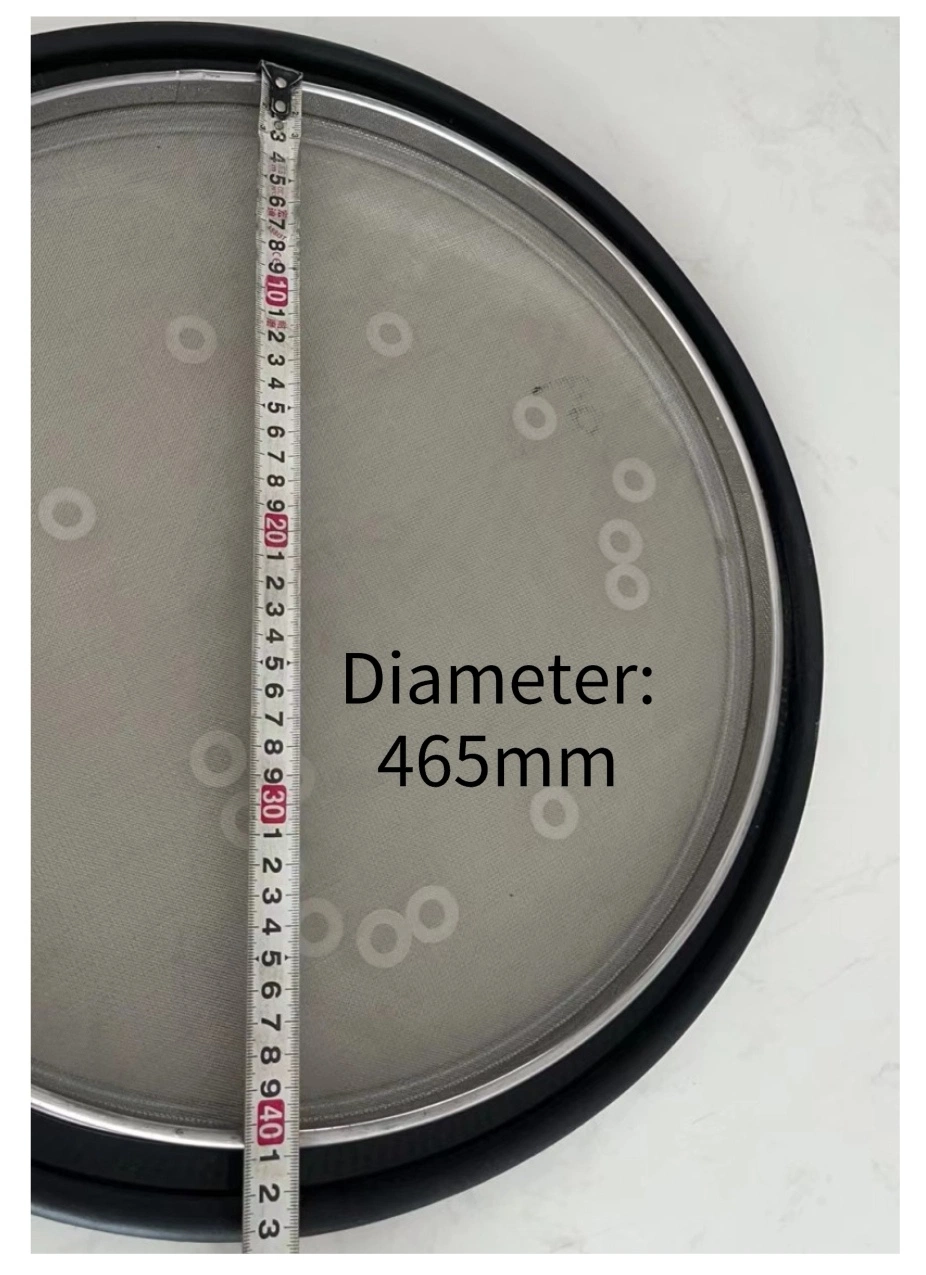

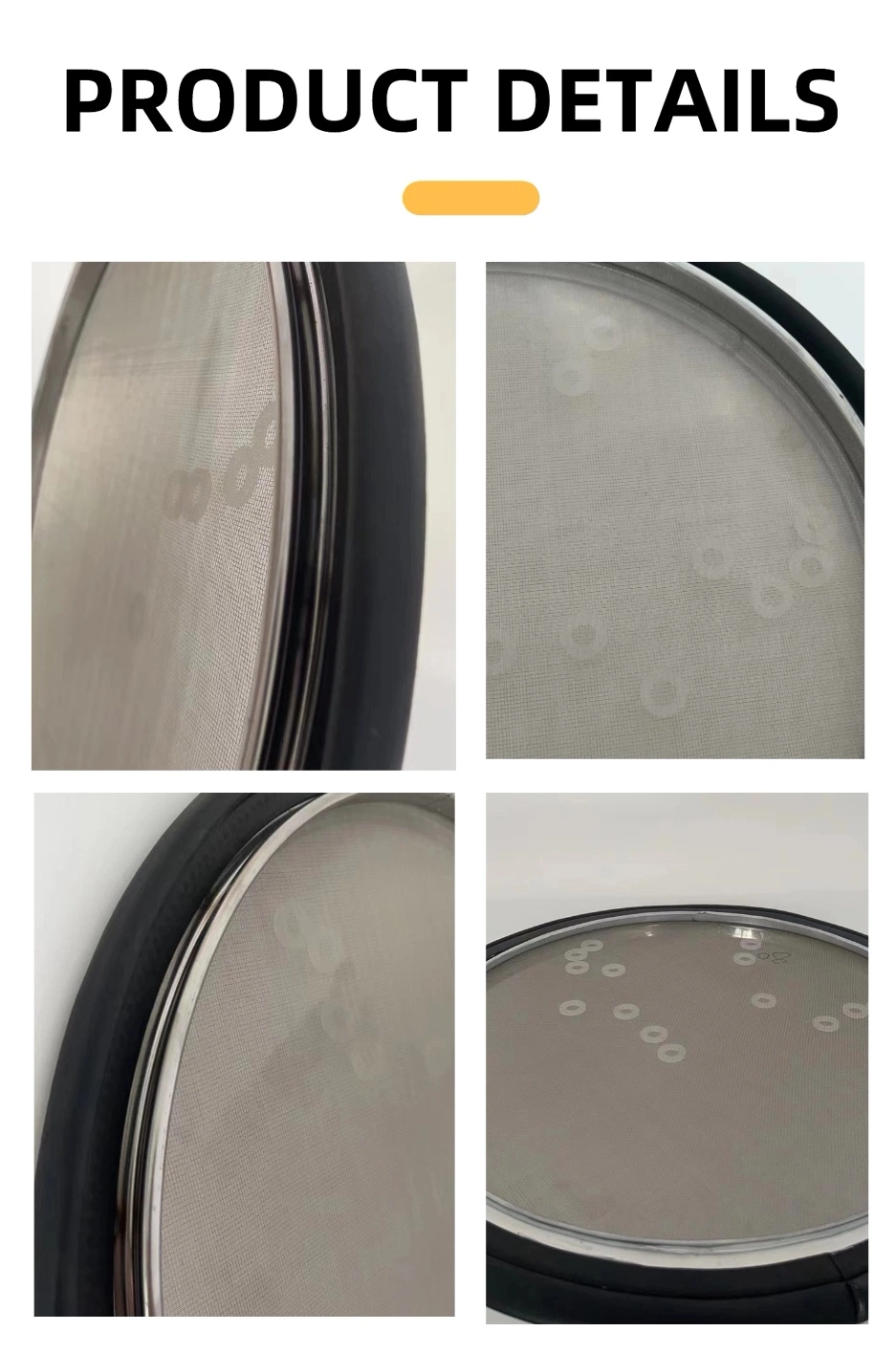

Product DescriptionPowder supply center introductionAn overviewThe structure of the powder supply center includes: powder supply room and chamber body, exhaust recovery chamber body, exhaust fan, filter element recovery, powder supply pump, powder supply bucket, powder bucket vibration platform, electric control system and other components. Note: THE recovery of exhaust recovery chamber, exhaust fan and filter element is only available in the powder supply center with its own recovery body.The working principle is to put the powder supply barrel filled with powder in the powder supply chamber body, and put on the vibration platform of the powder barrel, and then connect the fluidized air to make the powder not fluidized. The vibration platform vibrates intermittently. The dust generated in the fluidization process will not overflow through the rear exhaust pipe. During the operation of the spray gun, the feeding pump station will drop, so that the suction tube is inserted into the fluidized powder. The pump station is controlled to descend through the powder level detection sensor, so that the suction tube is always inserted into the upper fully fluidized part of the powder. With the continuous decline of powder level, when the powder level reaches the lower limit, the electric control system in the powder supply center will send out sound and light alarm and text prompt on the touch screen. Remind the operator of low powder level alarm, need to add powder! In THE process OF cleaning, lower the pump bottom to the powder cleaning level, open the powder cleaning, the powder supply center will automatically clean the powder supply pipeline on both sides of the spray gun alternately. If you need to change the color, simply raise the pump station to a high point, you can easily lift out the powder supply bucket, and then lift into the desired color of the powder supply bucket.characteristics:Characteristic one: The powder is not fluidized more smoothlyCharacteristic two: Maintain the effect of good working environmentFeature three: make the spray gun powder more uniformCharacteristic four: cut the bottom to liberate the operator, no longer by the spray gun powder problem.Feature five: greatly reduce the operator in the cleaning process of labor intensity and dust on the operator's healthFeature six: make the color change simple and convenientToner supply center for quick color changeThe exhaust system is connected with the large cyclone and spray booth, and the exhaust system with the large cyclone has an automatic butterfly valve;The roof of the powder supply center includes lighting;1.set of powder local fluidization system, which can directly pump powder from the powder box of the powder supplier;2. sets of powder supply barrels (with fluidization), volume 140 liters;Vibrating platform for powder box;Pneumatic piston lifting device for Venturi powder pump and powder suction pipe;The piston that clamps the compact;Automatic air blowing cleaning device for powder suction pipe and powder pump;Advantage1.Powder fluidization is smoother2. the effect of maintaining a good working environment3. make the powder supply of the spray gun more uniform4. completely liberate the operator, no longer troubled by the powder supply problem of the spray gun5.greatly reduce the labor intensity of the operators during the cleaning process and the impact of dust on the health of the operators6. Make color changing simple and convenientAutomatic Powder Supply CenterThe powder feed central system is designed for continuously, uniformly, quantificationally feeding powders to spraying equipment in automatic powder coating line. Since the cleaning of componenets and pipelines is automatically carried out by program, it is ideal for fast color change demands. Powder supply center maintains comfortable indoor environment by transferring partciculates during cleaning. Powder Supply Center Configurations & Features1.A sensor detects the powder position in the barrel, warning the lack of powder for continuous feeding.2.100lbs capacity powder barrel has a microporous plate which is meticulous and uniform for perfect fluidizing.3.A vibration powder siever ensures the purity of recovery powders, and increases powder utilization.4.Pulse-jet device automaticlly cleaning spray guns, injectors and pipeline rapidly5.PLC control system with touch screen panel and keyboard input, user-friendly to debug and operate.| Total Power | 500 W |

| Voltage | 110V/220V, 1P(can be customized) |

| Air Pressure | 15-30 min. (180° C) |

| Powder Hopper Capacity | 100L |

| Max quantity of injector to connect | 6-16pcs |